See below the article “ICT to Industry 4.0, the Journey thus far, and the Road Ahead” from the TIP (Technology Innovation Productization) Magazine, a publication jointly issued by WFEO Committee on Information and Communication (WFEO-CIC) and the Indian Technology Congress.

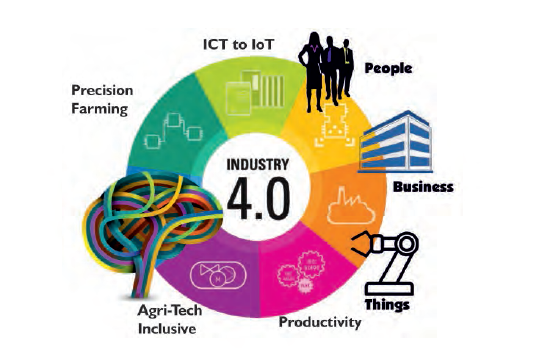

Internet information technologies has catalysed innovation across multiple industrial sectors, and ushered in a new, technology-driven global industrial revolution.

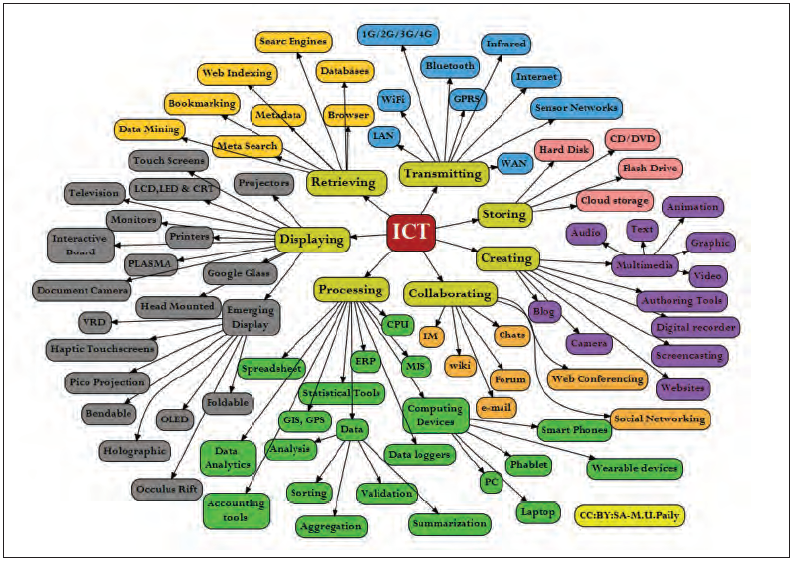

Mechanization and electricity were the catalysts for the earlier industrial revolutions, and have been recognized as General Purpose Technologies (GPTs). Over the last two decades, Information and Communications Technology (ICT) has emerged as the single-most pervasive GPT.

From its humble beginnings in facilitating tabulation and record keeping, ICT has grown over the years to applications for myriad needs including:

- Automating mundane;

- Repetitive processes;

- Inventory control and Just-in-Time inventory management;

- Organization-wide Enterprise Resource Planning (ERP);

- Customer Relationship Management;

- Supply Chain Management, amongst several others.

Over the years, ICT has transformed the way things are made by integrating contemporary technologies with new or optimized processes and methods of doing things.

ICT has a plethora of new technologies including Cloud Computing, Big Data and Internet of Things (IoT) that are enhancing automation, and driving increased digitalization, networking and connectivity; resulting in increased levels of industrial intelligence. These technologies have become the foci of innovation primarily because traditional industrial technologies have reached their full potential, and are not able to address present-day business challenges of compressing production time, slashing cost of production, increasing production flexibility resulting in an overall increase in business agility.

Internet technologies have scaled with accurate sensing and high-performance computing capabilities that facilitate efficient response to production requirements, making industrial production more visible and programmatically controllable. Cloud computing and Big Data along with rapid advances in data storage and data analytics are facilitating collaborative processing of large volumes of industrial data including supply chain, production, and marketing data.

Smart sensors and IoT are enabling high-frequency, real-time data collection during the production process, and this functionality is extremely helpful in monitoring physical systems and machinery; and controlling complex production processes in real time. High bandwidth broadband networks are helping efficient transmission of large volumes of industrial data between production locations for remote processing.

The integration of Internet with the manufacturing systems has led to the tectonic shift of Internet becoming a “core influencer and enabler” and transitioning from the erstwhile status as an “external factor”. Manufacturing enterprises are deploying Internet technologies across the entire value chain into manufacturing, R&D, services and marketing thereby streamlining the entire production process and operating model of the enterprise.

In India, many enterprises are adopters of ICT innovations, and are using new production technologies including robotics and 3D printing to build customized or personalized products.

They are using the ubiquitous broadband to transfer large volumes of data to control the production environment and facilitate closer engagement between suppliers, manufacturers and customers. The proliferation of sensors and the ability to acquire accurate data is driving “zero defect” production.

Digital Revolution: Industry 4.0 and Future Factories

Cutting-edge technologies are being developed that will change the way things are produced, resulting in Industry 4.0, or the fourth industrial revolution.

Industry 4.0 is a paradigm that will see machines collaborating seamlessly and performing increasingly complex tasks; accurately predicting downtimes and failures, and triggering maintenance processes; and perhaps even ‘selforganizing’ themselves to respond to unscheduled disruptions in the production line.

Present-day manufacturing automation systems are oriented towards high-volume/low-mix production with centralized control. Future factories will have a plethora of sensors that would be acquiring measurements continuously, and robotic systems that have significantly higher levels of intelligence and decision-making capabilities. The production setup will metamorphose from a high-volume/low-mix (large numbers of standardized products) to a high-mix/low-volume (many customized products) paradigm as products will be more closely tailored to a customer’s requirements.

Tomorrow’s businesses will need to collaborate with partners and suppliers to collaboratively design new products, or optimize supply chains by sharing production lines and facilities. This will require a ‘plug and play’ infrastructure that is flexible and secure for sharing data.

Data infrastructure will increasingly be powered by cloud technologies; and distributed ledgers or blockchains will be shared and accessed by users without the need for centralized data infrastructure. Data will be available to trusted parties, and other classes of users will be able to perform certain algorithms on the encrypted data and view results using homomorphic encryption technologies.

Analytics technologies including Big Data will be used to ‘mine’ and ‘discover’ patterns and linkages in data that can be used to provide insights from the shop floor to the top-floor. Machine learning and artificial intelligence technologies will be deployed to identify patterns for predictive and prescriptive analytics (presenting options to the users).

Way Forward…

While the proliferation of these technologies has resulted in enhancing affordability, the Micro, Small and Medium Enterprises (MSME) face the challenge of ‘leap-frogging’ the technology ladder, and quickly moving through the stages of electrification, automation, and digitisation to achieve the status of ‘smart factories’. To seamlessly make the transition, MSME units will need to focus on upgrading the existing equipment to deploy sensors and enable networking and connectivity.

A critical piece for the MSME in the adoption of contemporary technologies and expanding their operations is the skills gap. Manufacturers and related organizations, academia, research organizations, engineering professional organizations, and the Government will need to work together in a cohesive manner to develop innovative solutions to bridge the skills gap and create a pipeline of employable future-proof manufacturing professionals.

Many nations have embarked on an ambitious mission to strengthen their national manufacturing sectors to ensure economic advantage in the global comity of nations, and are aspiring to develop bestin-class manufacturing infrastructure in their countries.

Professional societies including the WFEO as custodians of the cumulative experience and expertise of interdisciplinary practicing engineers will need to work with the technology providers, Government, and the MSME units to minimize disruption; protect the investments made; adopt a conservative approach to identify and implement long duration investment cycles, enhance the quality of engineering education and develop industry-specific advanced personalized learning courses that will support the Government initiatives to make nations self-sufficient and strengthen the manufacturing sector.

![]() Download the full magazine

Download the full magazine

OCT

2017